In the rapidly evolving landscape of manufacturing, the integration of generative AI is becoming increasingly crucial. This technology heralds a new era of innovation, enhancing product design, optimizing processes, and elevating quality control. As industry leaders anticipate the future, the judicious application of generative AI is not just beneficial but necessary.

The Advantages of Generative AI for the Manufacturing Industry

Generative AI serves as a catalyst for numerous advancements in manufacturing.

- Innovative Design: It plays a pivotal role in conceiving novel product designs by synthesizing current trends, market demands, and consumer behaviors, fostering the creation of unique and competitive products.

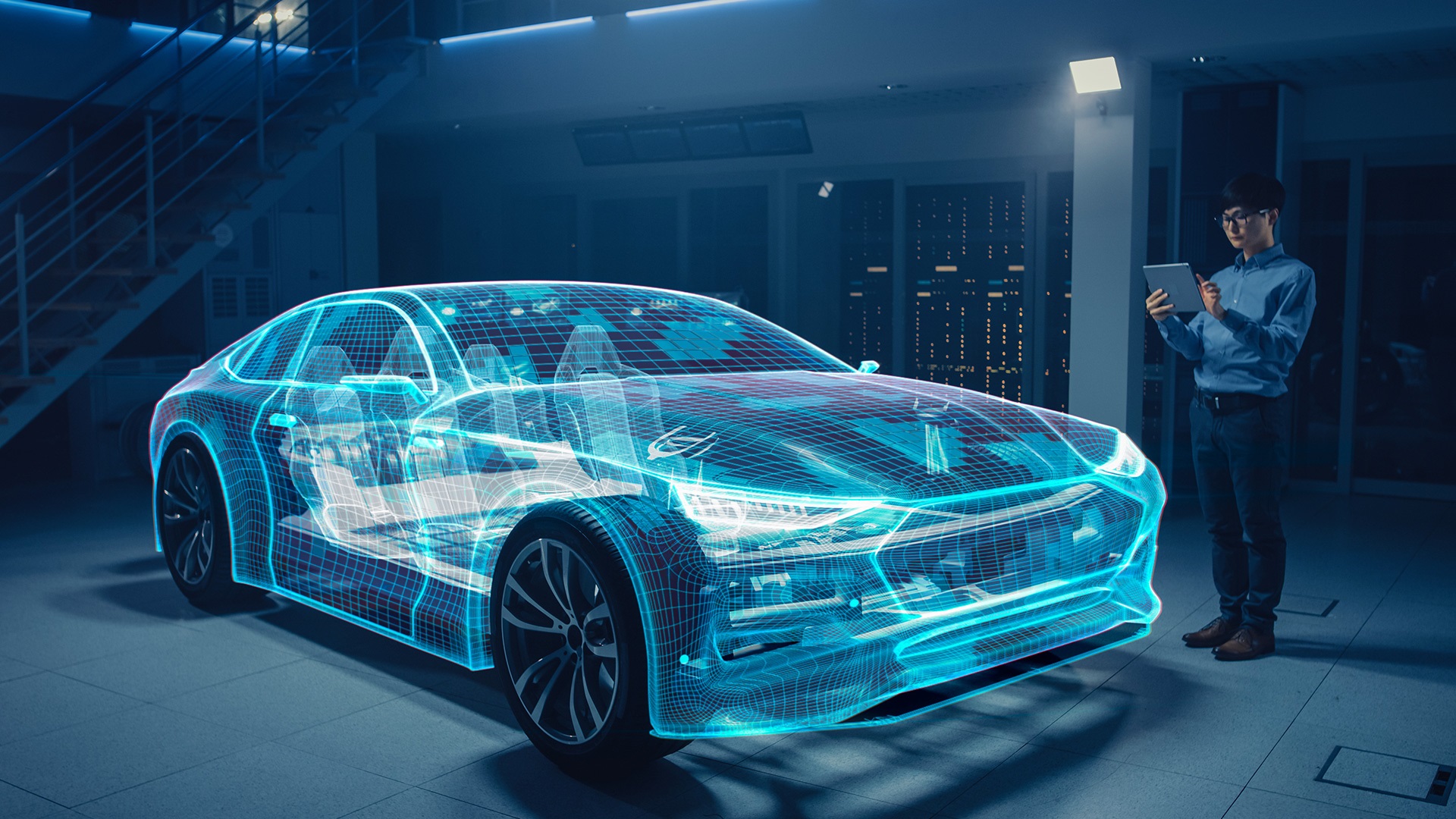

- Rapid Prototyping: By accelerating simulation and prototyping, generative AI enables the swift creation of 3D models, refining design and diminishing the reliance on physical prototypes.

- Process Enhancement: Leveraging data from sensors and machinery, this AI can pinpoint inefficiencies, thereby reducing waste and downtime while boosting quality control.

- Supply Chain Efficiency: It predicts demand, optimizes inventory, and streamlines logistics, substantially reducing operational costs.

- Quality Assurance: Employing predictive analytics and computer vision, generative AI for manufacturing foresees potential defects, ensuring a higher product quality reaches the consumer.

- Customization: It enables mass customization, allowing for products tailored to individual preferences, which can significantly heighten customer satisfaction.

- Energy Management: By analyzing energy data, generative AI recommends adjustments that lead to cost savings and reduced environmental impact.

- Predictive Maintenance: Gen AI anticipates equipment failures, facilitating proactive maintenance in manufacturing that curtails repair costs and production delays.

- Resource Optimization: Generative AI proposes methods to enhance material usage, optimizing the allocation of resources.

- Workforce Development: It also extends to training, offering simulation-based learning that sharpens the skills of manufacturing personnel.

Navigating the Challenges

Despite its potential, integrating generative AI into manufacturing is not without its hurdles.

- Data Integrity: AI models require substantial, high-quality datasets, often a challenge for companies with non-digitalized, scattered legacy systems.

- Security and Privacy: Protecting sensitive data is paramount, necessitating robust cybersecurity measures to safeguard intellectual property.

- Initial Costs: The financial outlay for AI implementation can be prohibitive, especially for smaller enterprises.

- Expertise Scarcity: A shortage of AI specialists calls for significant investment in training or recruitment.

- System Compatibility: Integrating AI with outdated manufacturing systems can be challenging.

- Regulatory Compliance: Manufacturers must navigate stringent industry regulations, ensuring AI applications are transparent and compliant.

- Ethical Use: As AI autonomously generates content, ethical considerations, particularly in sensitive industries, must be addressed.

- Consumer Confidence: Maintaining trust is crucial, necessitating clear communication regarding AI’s role in product safety and quality.

- Organizational Change: The shift to AI-driven processes can encounter resistance, requiring effective change management strategies.

- Sustained Maintenance: AI systems require ongoing support to remain effective and secure.

Forging Ahead to Industry 5.0: Hexaware’s AI Solutions

As the manufacturing sector advances towards Industry 5.0, manufacturers must adopt a comprehensive approach to generative AI that encompasses technological, organizational, ethical, and strategic facets. However, undertaking such a challenge alone is risky. Finding a strong IT partner who understands generative AI is critical to gaining the support you need. Hexaware Technologies stands at the forefront, offering tailored AI solutions that align with key strategic considerations for a seamless transition.

- Digital Maturation: Hexaware supports manufacturers in establishing a robust digital backbone, pivotal for integrating smart, interconnected systems that lay the groundwork for advanced AI applications.

- Data Governance: With Hexaware’s expertise, companies can ensure their data is managed and governed to the highest standards, essential for the precision and effectiveness of AI models.

- Talent Cultivation: Hexaware aids in upskilling the existing workforce and provides access to AI and data science experts, thereby bridging the talent gap and fostering an environment of continuous learning and innovation.

- Security Prioritization: Hexaware emphasizes the importance of cybersecurity, offering solutions to protect sensitive data and intellectual property in an increasingly interconnected manufacturing landscape.

- Compliance Assurance: Navigating the complex regulatory environment, Hexaware helps ensure that AI deployments are fully compliant with industry-specific standards and practices.

- Ethical Frameworks: Recognizing the ethical implications of AI, Hexaware assists in the creation of ethical policies and practices, ensuring responsible deployment of AI technologies.

- Workforce Engagement: Hexaware’s change management strategies are designed to prepare the workforce for AI adoption, supporting education and training initiatives that facilitate the transition to AI-enhanced operations.

- Infrastructure Investment: Depending on the level of AI adoption, Hexaware can guide the necessary infrastructure enhancements to support the computational needs of advanced AI applications.

- Collaborative Innovation: Hexaware encourages collaboration with AI tech providers, academic entities, and industry partners, fostering a synergistic ecosystem essential for the success of Industry 5.0.

- Sustainability Alignment: With a focus on sustainability, Hexaware ensures that AI initiatives contribute to eco-friendly practices, helping manufacturers reduce waste and optimize energy usage.

- Business Case Development: Hexaware assists in articulating a clear business case for AI investments, demonstrating tangible ROI and the strategic advantages of AI adoption in the manufacturing sector.

Through its comprehensive suite of AI capabilities, Hexaware is poised to guide manufacturers through each strategic consideration, ensuring that the journey towards Industry 5.0 is as innovative as it is seamless. Partner with us to leverage generative AI and redefine the future of manufacturing.

Contact marketing@hexaware.com for a detailed exploration tailored to your organization’s needs.